Outdoor furniture is subject to the harsh tests of the natural environment every day. In this protracted battle against nature, short-fiber polyester, with its outstanding durability and resistance to environmental stress, is becoming the preferred fabric for high-end outdoor furniture manufacturing.

The global short-fiber market reached a scale of 21.571 billion US dollars in 2024, with polyester materials accounting for the largest share (30%). Its growth is partly driven by the expansion of outdoor living demand and breakthroughs in material performance.

---

I. Challenges of Outdoor Living and Material Evolution

Traditional outdoor furniture materials are confronted with three major predicaments: natural fibers are prone to mold and rot in a humid environment, ordinary synthetic fibers age rapidly under ultraviolet radiation, and metal frames are easily corroded without proper protection. These pain points have pushed up the maintenance costs and replacement frequency of outdoor furniture. The rise of short-fiber polyester marks a significant evolution in outdoor furniture materials. Unlike long-fiber polyester, short-fiber polyester is made by spinning polyester polymers, cutting them into short fibers of several to tens of centimeters, and then spinning them into yarns to weave fabrics.

Ⅱ.This structure endows it with a unique combination of performances.

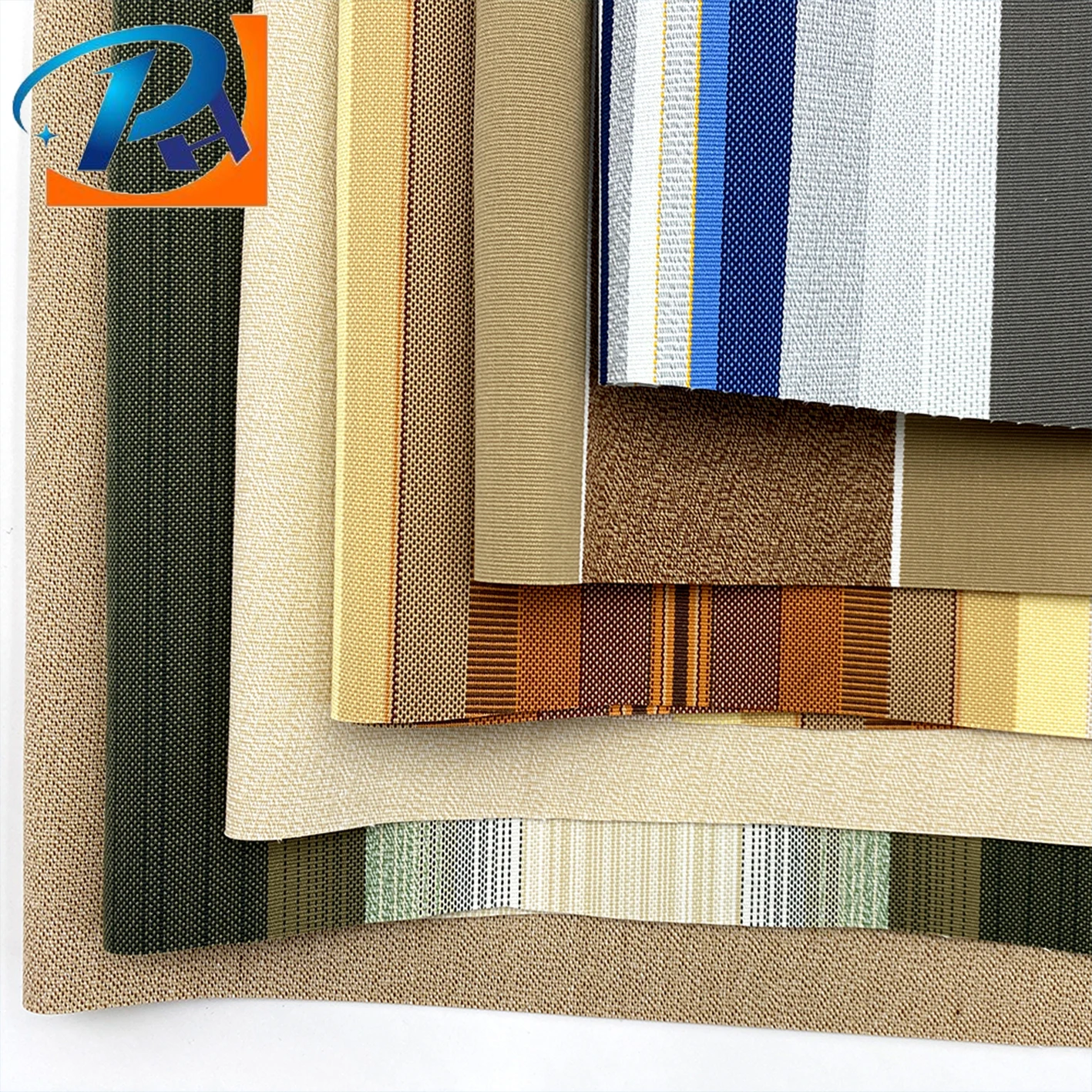

Morphological differences determine functional characteristics: The fibers in short-fiber polyester yarns are discontinuously arranged, forming more abundant air pores, which brings better air permeability and thermal insulation. While long-fiber polyester has a smooth surface and a compact structure, it has better water resistance but a harder touch. It is precisely these microstructure differences that make short-fiber polyester an ideal surface material and filling material for outdoor furniture.

Second, the five core characteristics for conquering outdoor environments

1. Super weather resistance

Short-fiber polyester has top-notch lightfastness and thermal stability among synthetic fibers. Its UV resistance can last for more than 500 hours without significant fading or aging. This enables polyester outdoor furniture to maintain color stability under strong sunlight and prevent premature aging and yellowing. Its heat resistance range is as wide as -70℃ to 170℃. Whether it is the winter in extremely cold regions or the scorching heat in desert areas, the fabric will not become brittle or soften and deform. This thermal stability enables polyester furniture to maintain structural integrity even under extreme climatic conditions.

2. Excellent physical properties

The strength of polyester fiber is nearly twice that of cotton and three times that of wool, endowing furniture fabrics with excellent tear and puncture resistance. Its wear resistance ranks second among synthetic fibers, only after nylon, ensuring that the surface of furniture does not pill or wear out and thin under high-frequency use. Sharp objects such as sand grains and branches in outdoor environments cannot easily scratch polyester fabric, which greatly extends the service life of furniture.

3. Waterproof, stain-resistant and easy to clean

The low water absorption of polyester is its core advantage as an outdoor material - the moisture absorption rate is only 0.4%, which is much lower than the 8.5% of cotton. This characteristic causes rainwater to roll off in beads on the surface and not seep into the internal filler. Short-fiber polyester furniture fabric can resist common stains such as coffee and fruit juice. Daily maintenance only requires wiping with a damp cloth to restore cleanliness, significantly reducing the difficulty of care.

4. Color durability

Although polyester has poor dyeability, once colored, its color fastness is extremely high and it is not easy to fade. This feature enables outdoor furniture to maintain bright colors even after long-term exposure to ultraviolet rays and repeated cleaning, meeting the aesthetic demands of modern courtyards.

5. Environmental adaptability

The recycled polyester staple fiber technology recycles and regenerates used polyester bottle chips, spinning waste filaments, etc., endowing the materials with a "second life". High-end outdoor furniture brands are adopting such recycled materials on a large scale, which not only reduces production costs but also meets the concept of environmental protection.

---

The dominance of polyester staple fiber in the field of outdoor furniture is still strengthening. According to industry forecasts, the global staple fiber market is expected to maintain a compound annual growth rate of 3.8% from 2024 to 2029, with functional polyester varieties becoming the main growth engine. Short-fiber polyester does not have the romantic story of natural fibers, but with the precise performance of synthetic materials, it has reshaped the comfortable boundary between humans and nature

# Outdoor Furniture # Polyester Technology # Sustainable Design # Outdoor Living # Functional Fabrics

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

FA

FA